MAINTENANCE & TESTING

MAINTENANCE & TESTING

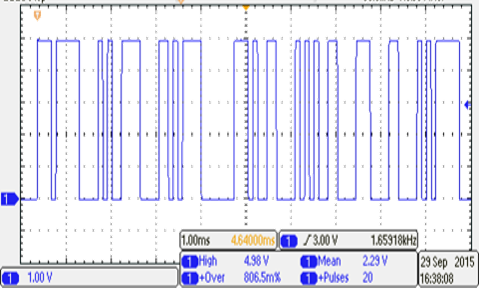

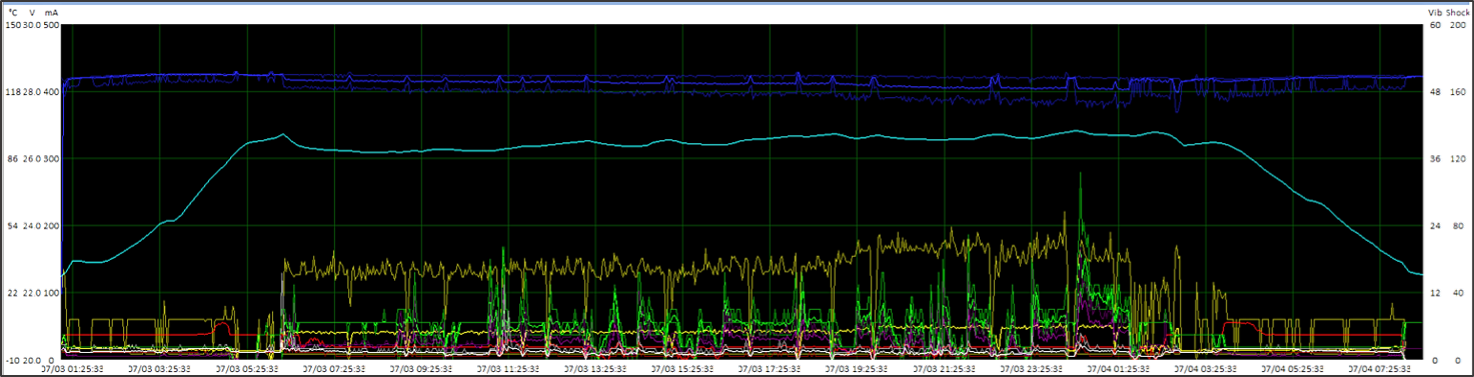

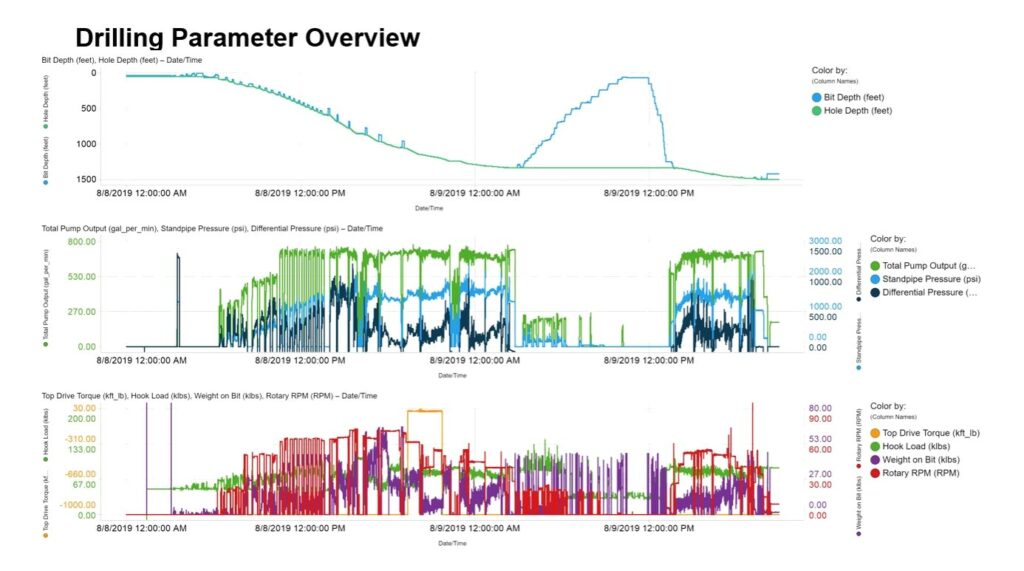

DD Innovation’s Digital Blue PrintingTM is our proprietary process that ensures every circuit board in our MWD systems are operating to original manufacturing specification. State of the art testing equipment and facility allows us to test our components both at ambient and elevated temperatures to ensure our tools circuits are firing with exact tolerances for current, voltage and logic level timing. Our tools are tested at stringent operating intervals to prevent premature failures and optimize success for long hour runs in our customer’s wells.